Art History/Craft History, Craft, Handloom, Art, Monographs, Research

Cotton: A Probe into Archaeological Evidences

Gupta, Dr. Charu Smita, Pathak, Anamika

October, 2009

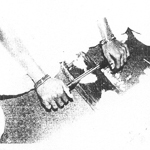

The cotton fibres (Pl. 1) belong to the genus Gossypium of family Malvaceae. About 39 species are known worldwide, native to the tropics and warm temperate region (http./www.cottonsjourney.com). Some scholars have discussed cotton varieties in detail (Watt 1966: 575-589). Among all, only four popular varieties have been used for domestication. These are Gossypium arboreum, Gossypium herbaceum, Gossypium hirsutum and Gossypium barbadense. First two varieties belong to old World and are usually known as desi cotton, while other two are of new World. (Cotton committee report, 1963:1)

Some scholars are of the opinion that Gossypium herbaceum is a wild ancestor to old World cottons, which is endemic to South Africa (Phillips 1976: 196), whether this is a place of origin for all old World cottons is contested (Santhanam and Hutchinson 1974: 90). Few other scholars think that Gossypium arboreum is a domestic form of cotton, which is widely cultivated in Indian sub-continent region from very early period (Possehl 1999: 249). Physical characteristic of the Gossypium herbaceumcotton is generally much longer in staple. On the other hand Gossypium arboreum variety of cotton is predominantly coarse short stapled; though a few among them are medium to long stapled and fairly fine. Some scientists feel there are weedy, ‘feral’ varieties of Gosssypium arboreum available in the fields of India and Pakistan. These have a range ...

Some scholars are of the opinion that Gossypium herbaceum is a wild ancestor to old World cottons, which is endemic to South Africa (Phillips 1976: 196), whether this is a place of origin for all old World cottons is contested (Santhanam and Hutchinson 1974: 90). Few other scholars think that Gossypium arboreum is a domestic form of cotton, which is widely cultivated in Indian sub-continent region from very early period (Possehl 1999: 249). Physical characteristic of the Gossypium herbaceumcotton is generally much longer in staple. On the other hand Gossypium arboreum variety of cotton is predominantly coarse short stapled; though a few among them are medium to long stapled and fairly fine. Some scientists feel there are weedy, ‘feral’ varieties of Gosssypium arboreum available in the fields of India and Pakistan. These have a range ...

Some scholars are of the opinion that Gossypium herbaceum is a wild ancestor to old World cottons, which is endemic to South Africa (Phillips 1976: 196), whether this is a place of origin for all old World cottons is contested (Santhanam and Hutchinson 1974: 90). Few other scholars think that Gossypium arboreum is a domestic form of cotton, which is widely cultivated in Indian sub-continent region from very early period (Possehl 1999: 249). Physical characteristic of the Gossypium herbaceumcotton is generally much longer in staple. On the other hand Gossypium arboreum variety of cotton is predominantly coarse short stapled; though a few among them are medium to long stapled and fairly fine. Some scientists feel there are weedy, ‘feral’ varieties of Gosssypium arboreum available in the fields of India and Pakistan. These have a range ...

Some scholars are of the opinion that Gossypium herbaceum is a wild ancestor to old World cottons, which is endemic to South Africa (Phillips 1976: 196), whether this is a place of origin for all old World cottons is contested (Santhanam and Hutchinson 1974: 90). Few other scholars think that Gossypium arboreum is a domestic form of cotton, which is widely cultivated in Indian sub-continent region from very early period (Possehl 1999: 249). Physical characteristic of the Gossypium herbaceumcotton is generally much longer in staple. On the other hand Gossypium arboreum variety of cotton is predominantly coarse short stapled; though a few among them are medium to long stapled and fairly fine. Some scientists feel there are weedy, ‘feral’ varieties of Gosssypium arboreum available in the fields of India and Pakistan. These have a range ...

PRACTITIONERS: INDIA

Access 70,000+ practitioners in 2500+ crafts across India.

BIBLIOGRAPHY

10,000+ listings on arts, crafts, design, heritage, culture etc.

GLOSSARY

Rich and often unfamiliar vocabulary of crafts and textiles.

SHOP at India InCH

Needs to be written.