Mat-weaving as an art form is traced back to ancient times in India, with sages traditionally being depicted as meditating seated on woven mats, as indicated by an old Bengali proverb, as well as by texts in the Vedic corpus of religious texts. The craft – both mat-weaving and basketry – is described by Kamladevi Chatopadhyaya as ‘interlacing’ two or more strands of the material (reeds, leaves, rushes, cane, bamboo, palm leaves) in different ways, a description that bespeaks an inherent simplicity, but still hints at the poetry of weaving mats and baskets from strips of reeds and leaves.

The craft of mat-weaving is basically a utilitarian rural tradition to create items of everyday use from the raw materials available in profuse quantities in the sub-tropical marshy and wet regions of West Bengal. Mats for sitting on and sleeping on, baskets for carrying and storage, and hand-fans for helping endure the heat are a few of the common products that are made. Different kinds of mats and baskets are made in different areas of West Bengal, depending on the particular reed or grass that is easily available, the weaving traditions specific to an area, and the needs of the local populace.

The craft of mat-weaving is basically a utilitarian rural tradition to create items of everyday use from the raw materials available in profuse quantities in the sub-tropical marshy and wet regions of West Bengal. Mats for sitting on and sleeping on, baskets for carrying and storage, and hand-fans for helping endure the heat are a few of the common products that are made. Different kinds of mats and baskets are made in different areas of West Bengal, depending on the particular reed or grass that is easily available, the weaving traditions specific to an area, and the needs of the local populace.

Well-known (perhaps the most well-known) among the various mats from West Bengal is the sitalpati mat, made from green cane slips of the Maranta dichotoma which are split into very fine slices length wise. This mat is another exposition of the skill of ‘joining grass with grass and interlacing leaves’ to weave an item that is comfortable, utilitarian and beautiful. The quality of the sitalpati mat is judged by its glossiness, smoothness and fineness of texture. It is said that the best kind of sitalpati is so smooth that even a snake cannot glide over it. The word sital or sheetal means cool and the sitalpati mat is famous for the feeling of cool it imparts to the person sitting or sleeping on it. This particular quality of the sitalpati is particularly apt for the warm and humid climate of West Bengal. Mats in general – and sitalpati mats in particular – although defined primarily as a rural craft, linked intimately with everyday life are, however, now available outside of the hinterlands of West Bengal; the aesthetic appeal and utilitarian value of these mats have made them increasingly visible in large towns and metropolitan cities, that is, outside of their traditional market.

The sitalpati mat is made in the northern Cooch Behar district of West Bengal (as well as in the neighbouring states of Tripura and Assam; and in Bangladesh, which was East Bengal in an undivided subcontinent). In West Bengal it is woven dominantly by members of the kayastha caste. (The kayasthas rank below the brahmins but above the mahisyas who weave the popular and less expensive madur mats, with the production concentrated in Midnapore district of East Bengal.) Among the areas in Cooch Behar where sitalpati mats are woven, Sagareswar Ghugumari and Pashnadanga are important centres.

RAW MATERIAL & TECHNIQUE

The raw material for sitalpati mats is mutra cane, which is grown in Cooch Behar. This cane grows in marshy and swampy spots and, according to Pradeep Das – a sitalpati mat-weaver from Ghugumari – is cut all year round. The cane is split with a sickle-like instrument with a long blade (about a foot long) known as dao. The green cane slips are washed in soda, dried, split into even sized pieces or strips and then soaked in water for several hours – often for 24 hours – before being slashed into thin strips. Pradeep Das states that each reed is slashed into 14-15 strips; each strip is wet again to make it pliable and then each strip is split into a further three strips. According to Pradeep Das, the topmost among the three strips is the coolest and it is this that is used to make the sitalpati; the other two strips are warmer and are used for weaving other mat or basketry items that do not impart the coolness that a sitalpati mat does.

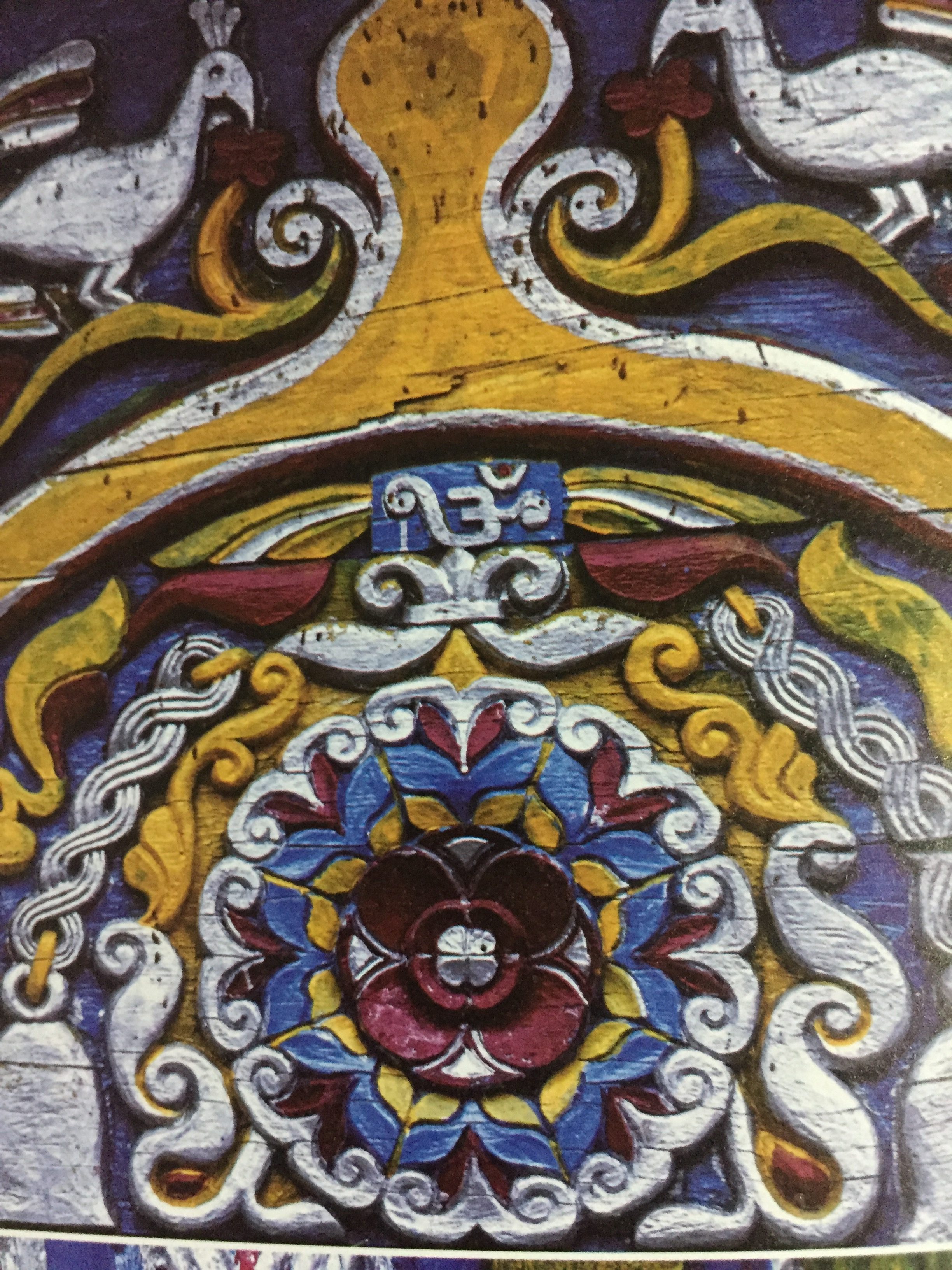

A minimum of tools are used to weave these mats; the critical techniques involve the creation of thin, smooth and pliable strips, and the comfort and aesthetic appeal are determined by the weaver’s skill, weaving action, and innovativeness with weave and colour. There are few set rules about deigns and patterns but coloured motifs are usually created in bands along the edges only. Coloured motifs and patterns are created by weaving a colour dyed weft with a natural cream-brown warp. The extra weft technique is used for creating stylised human, animal and leaf motifs.

A minimum of tools are used to weave these mats; the critical techniques involve the creation of thin, smooth and pliable strips, and the comfort and aesthetic appeal are determined by the weaver’s skill, weaving action, and innovativeness with weave and colour. There are few set rules about deigns and patterns but coloured motifs are usually created in bands along the edges only. Coloured motifs and patterns are created by weaving a colour dyed weft with a natural cream-brown warp. The extra weft technique is used for creating stylised human, animal and leaf motifs.

PRODUCTION & SALE

The making of sitalpati mats has been adopted as a profession by entire families. According to Pradeep Das’ estimate, about 50,000 people in the district of Cooch Behar pursue sitalpati mat-weaving as a livelihood, with the entire family participating in the work and helping in whichever part of the process they are most adept at. Pradeep Das states that a mat that is 4 feet by six feet takes about a day and a half to weave, the wetting, drying and dyeing process being separate.

The making of sitalpati mats has been adopted as a profession by entire families. According to Pradeep Das’ estimate, about 50,000 people in the district of Cooch Behar pursue sitalpati mat-weaving as a livelihood, with the entire family participating in the work and helping in whichever part of the process they are most adept at. Pradeep Das states that a mat that is 4 feet by six feet takes about a day and a half to weave, the wetting, drying and dyeing process being separate.

Gallery

YOUR VIEWS

PRACTITIONERS: INDIA

Access 70,000+ practitioners in 2500+ crafts across India.

BIBLIOGRAPHY

10,000+ listings on arts, crafts, design, heritage, culture etc.

GLOSSARY

Rich and often unfamiliar vocabulary of crafts and textiles.

SHOP at India InCH

Needs to be written.