Harital an unusual paper has been in use in Nepal for many hundreds of years. The paper gets its name from harital (arsenic sulphide), a yellow mineral ore that is one of the ingredients that goes into the making of this paper. This archival and manuscript paper has been used for inscribing religious texts and manuscripts, and ancient scriptures, for casting horoscopes, as a base for paintings, and for the writing of documents of import like land records. The base of this paper is the indigenous Daphne (lokta) paper that undergoes complex treatment in the hands of knowledgeable specialists before its conversion into harital paper, which has a thick and weighty texture and a golden hue.

On studying old manuscripts and records written on harital paper in museums and in private collections it is apparent that in spite of its antiquity the paper retains its colour and strength. It is necessary to use special inks on this paper – the most suitable are the locally produced black, gold, and silver inks. Harital paper is also highly valued as it is immune to moths and insects which, along with climatic factors, are the greatest enemy of paper.

PROCESS & TECHNIQUE

Flawless lokta papers, of the highest quality, are selected. The sheet of lokta is spread over a smooth surface and a thin coat of an adhesive – prepared by washing, drying, and pulverising rice grain into powder – is carefully applied on to it. Another sheet of lokta paper is placed exactly over the first sheet and stuck on evenly without any wrinkles. Depending on the thickness required, any number of sheets can be added on following the same process. The sheets are then thoroughly dried.

Manasila, a substance of mineral origin, orange in colour, and with anti-insect properties is powdered in a mortar and mixed with the harital powder. Both these powders are then well mixed with the rice powder adhesive. When this mixture is ready, a dried sheet of the prepared paper is again spread out over a smooth surface. The harital, manasila, and rice adhesive mixture is spread uniformly over the paper in a thin and even layer. The paper now becomes yellow in colour and is again carefully dried. This process is normally followed for only one side of the paper. The fully dried sheets are then cut to the size required.

The sheets are now ready to be polished. A smooth, round mineral stone (luluga) or a conch-shell is used – the sheet is continuously rubbed with it until it is uniformly smooth and glossy all over. This process is repeated on both sides.

Traditionally, the harital papers have lines drawn on them to facilitate and aid the writer. For this a wooden plank slightly bigger in size than the sheets is used, with thick threads stretched in parallel lines to the width required.

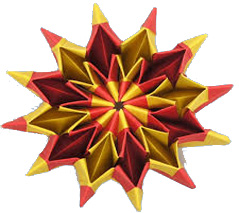

Gallery

YOUR VIEWS

PRACTITIONERS: INDIA

Access 70,000+ practitioners in 2500+ crafts across India.

BIBLIOGRAPHY

10,000+ listings on arts, crafts, design, heritage, culture etc.

GLOSSARY

Rich and often unfamiliar vocabulary of crafts and textiles.

SHOP at India InCH

Needs to be written.